Maintenance & Servicing

One of our activities is Maintenance & Servicing in accordance with DIN 31051 (maintenance, inspection, repair and upgrading) of machinery and technical systems and equipment, irrespective of type and make – conventional or automatically controlled. Our service range stretches from simple machine cleaning via basic maintenance (overhaul), modernisation to critical-point analyses.

Where required, we also relocate machines or technical systems from A to B. Of course in a complete and coordinated effort – dismantling, transport, re-installation (including geometry) and start-up.

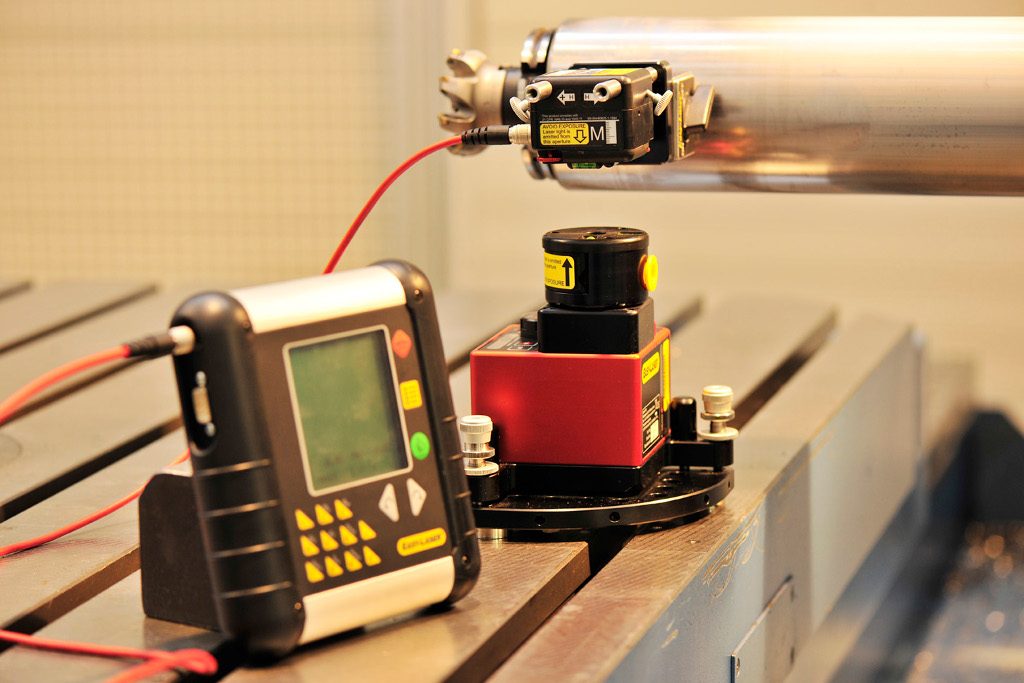

The consistent further development of our know-how and expertise with application of state-of-the-art measurement technology enables us to perform laser measurements as stand-alone or package projects. Measurement results are documented and evaluated with appropriate software solutions and analysis and test/inspection reports generated.

We also provide inspection services in compliance with valid codes and regulations for operational equipment, such as presses, hoisting equipment (cranes, lifting accessories), powered gates and electrical systems and installations.

Our Maintenance & Servicing program comprises the following:

- Maintenance

- Inspection

- Repair

- Upgrade

- Modernisation

- Retrofitting

- Geometry – Laser measurement

- System/equipment review

- Relocation

- Installation

- Start-up

- Spare part fabrication

We carry out relevant services for:

- Machines of all types and makes, conventional or controlled (including presses)

- Hoisting equipment – cranes, radio controls, lifting accessories ….

We are an outhorized “HBC – Service – Partner” for HBC – radio controls!

- Technical systems and installations

- Powered gates

- Vacuum-belt filters

- Welding systems and equipment

- Flame cutting systems and equipment

- Conveyor systems and equipment

- Electrical systems and equipment

- Control systems and equipment

- Hydraulic systems and equipment

- Pneumatic systems and equipment